Jaw stone crushers have come a long way in terms of design and functionality due to the advancement in technology. These changes have improved every aspect from operation to safety and maintenance, which has revolutionized the use of these mighty machines in fields like mining and construction. This article discusses the impact of the contemporary technology on jaw stone crusher machines and also the contribution of rock crusher distributors in availing the latest machines.

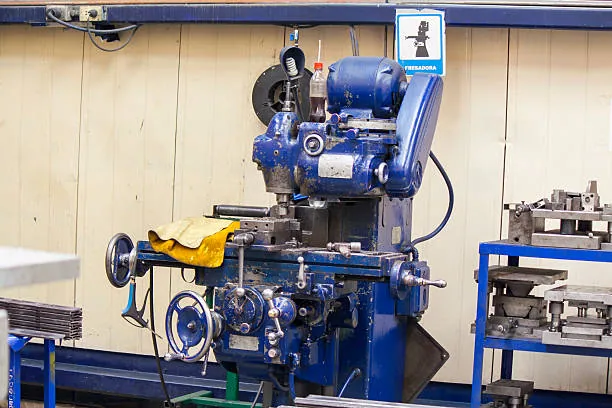

Advanced Materials and Manufacturing Techniques

The use of new materials and modern technologies in manufacturing has influenced the design of jaw stone crushers. Manufacturers are now using wear-resistant materials that help in increasing the life of the crushers and hence, the time taken for maintenance is less.

In addition, the accuracy of the tools used in digital machining means that all the parts are well fitted and thus there are few mechanical breakdowns.

Automation and Control Systems

Today, jaw stone crushers are being developed with automation and advanced control systems that improve the performance. These systems offer accurate control of the crusher settings, which makes it possible to make adjustments that enhance the crushing process. Automation also enables remote monitoring and control, which increases safety and optimizes the control of the crushing process.

Energy Efficiency Improvements

The jaw stone crushers have also been made more energy efficient due to the advancement in technology. New design techniques and technologies like the VFDs make the machines use less energy while at the same time providing the best crushing rates. This not only decreases the operational expenses but also minimizes the effects of mining and construction activities on the environment.

Safety Features

Security is always an issue of concern in any industrial process, and jaw stone crushers have not been left behind when it comes to this aspect due to technology. Other aspects such as the emergency stop button, hydraulic toggle systems, and others guarantee that the machines can be shut down in case of an emergency to avoid exposing the workers to danger.

Integration

The current development of jaw stone crushers also takes into account the integration of other crushing and screening equipment. This approach makes it possible to have the entire line of the crushing plant to be in harmony hence enhancing the productivity of the plant. Rock crusher distributors are also very important in offering turnkey solutions that include jaw crushers, cone crushers, screens, and other related equipment.

The use of technology has been very influential in the jaw stone crusher machine designs. These developments do not only improve the performance and productivity of the crushers but also make the processes more environmentally friendly. With the advancement in technology, rock crusher distributors and jaw stone crusher suppliers are some of the most important players in making sure that these advanced machines are available in the market for the industries. They assist industries in selecting the most appropriate equipment that is relevant to their operations and the latest technologies.